Compostable packaging.

Making sure that we minimise the impact of increased convenience from providing single serve sachets. We have partnered with one of Australia's most cutting edge packaging providers to minimise the impact of our packagingPaper

Paper sourced from FSC, PEFC accredited pulp, for every tree felled at least one more tree is grownNatureflex film

Natureflex film which is cellulose, made from sustainably grown eucalyptus trees from managed plantations.Bio-polymer

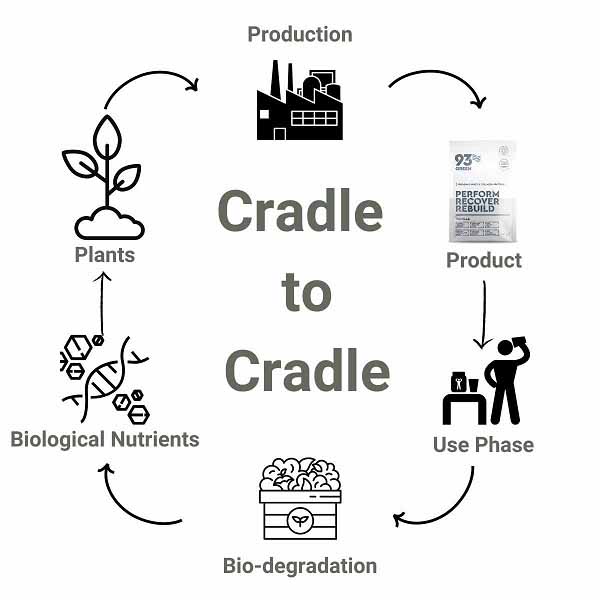

The bio-polymer is derived from natural resources such as sugarcane, cassava and corn from non-GMO crops.Cradle to cradle

Packaging that can be returned to nature after use. Learn moreWaste reduction

Designed to replace multi-layer barrier laminates that can’t be or aren’t being recycled.Does it breakdown in the ocean

We specifically selected our packaging supplier because they were able to identify that this was an important part of their packaging behaviour after use. Learn moreCertification

The film we use for our Premium 5 whey and collagen proteins is the only certified compostable multi-laminate in Australasia.If littered

No packaging should be littered but unlike Petrochemical based plastics our home compostable packaging will start to biodegrade in the presence of microbes, moisture and oxygen at ambient temperatures.

Biological Cycle

Cradle to cradle can be defined as the design and production of products of all types in such a way that at the end of their life, they can be truly recycled (upcycled), imitating nature’s cycle with everything either recycled or returned to the earth, directly or indirectly through food, as a completely safe, nontoxic, and biodegradable nutrient. With cradle to cradle, all the components of a product feed another product, the earth or animal, or become fuel: products are composed of either materials that biodegrade and become food for biological cycles or of technical materials that stay in closed-loop technical cycles, continually circulating as valuable nutrients for industry. It could be argued that cradle to cradle is equivalent to true sustainability – through the biological or technical components used, all products become sustainable as nothing becomes waste which cannot be reused.

Ocean breakdown?

8 million tonnes of plastic ends up in the oceans each year and by “2050 there’ll be more plastic in the sea than fish…” (Source: Ellen McArthur foundation – New Plastics Economy)

Packaging either petrochemical based or bio-based is not and should not be designed to be littered but as the figures above show it is happening.

We are independently testing our home compostable laminates in a marine environment (ASTM D7081) and we are seeing encouraging results regarding biodegradation. Our laminates are designed to break down at ambient temperature in the presence of microbes, water and oxygen and naturally biodegrade back into water, Co2 and biomass without eco-toxicity.